Quartz stones are also stain-resistant, scratch-resistant, easy to install, easy to clean, and low maintenance. Once they are installed on the wall, they require no more than an occasional wipe with a damp cloth to maintain their smooth surface and vibrant color. Too much maintenance.

|

Model Number |

V007 |

|

Material |

93% quartz sand and 7% resin |

|

Surface |

Polished/Leathered/Matte |

|

Package Type |

Fumigation Wooden Frame /Iron A Frame |

|

Warranty |

More than 5 years |

|

After-sale Service |

Online technical support |

The artificial quartz stone is flexible and its rich combination of colors gives itself with the texture and beautiful surface like the natural stone.

It can be widely used in public buildings (hotels, restaurants, banks, hospitals, exhibitions, laboratories, etc.) and home decoration (kitchen countertops, washstands, kitchen and bathroom walls, dining tables, coffee tables, window sills, door covers, etc.). It is an environmentally new building interior decoration material that is free of radioactive pollution and can be reused.

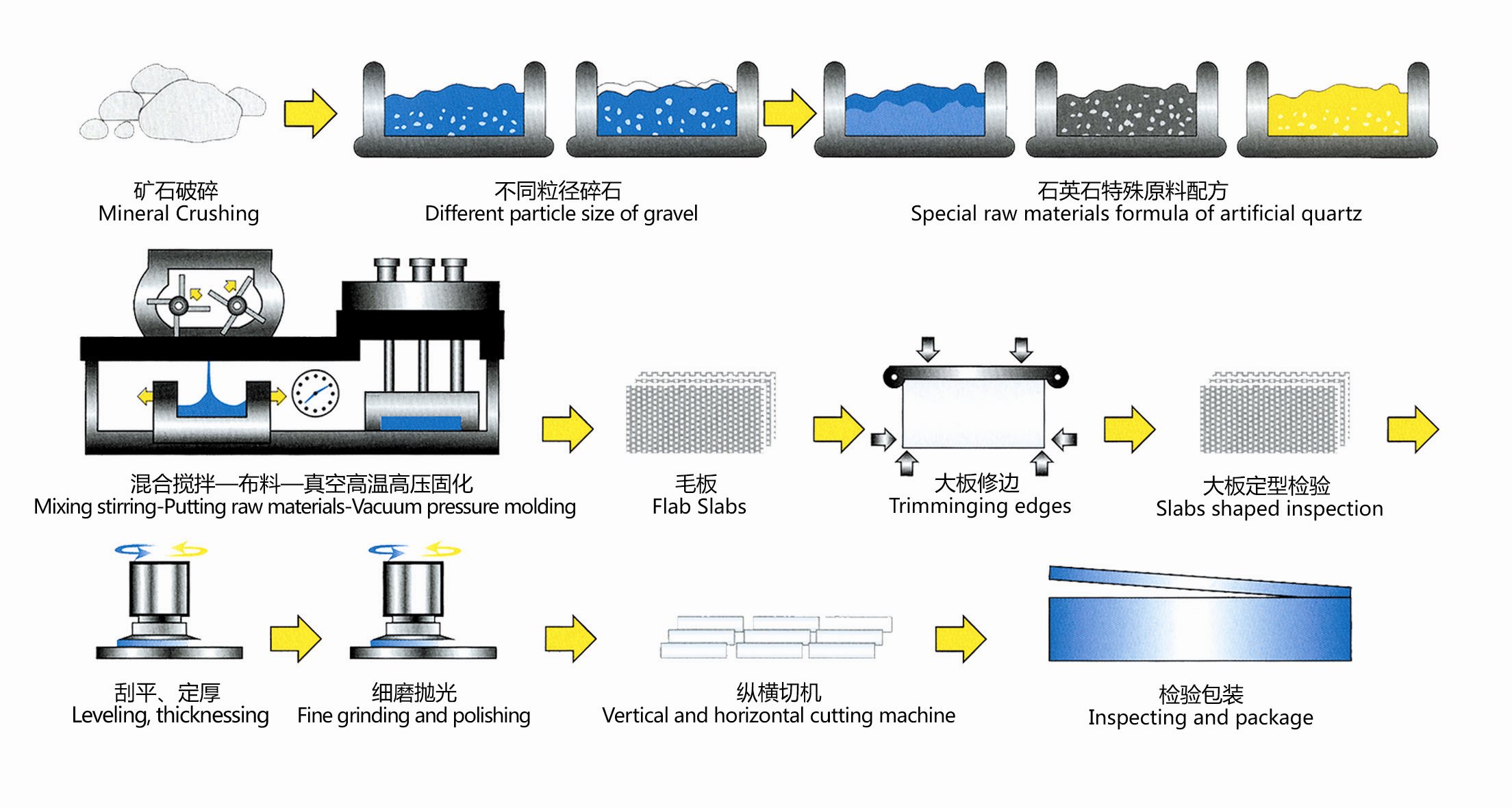

Mineral Crushing → Different particle size of gravel → Special raw materials formula of artificial quartz → Mixing stirring-Putting raw materials-Vacuum pressure molding → Flab Slabs → Trimminging edges → Slabs shaped inspection → Leveling, thicknessing → Fine grinding and polishing → Vertical and horizontal cutting machine → Inspecting and package

|

Test Item(s) |

Test Method (s) |

Test Result(S) |

|

Physical Properties |

||

|

Absorption by weight |

ASTM C97 |

0.03% |

|

Density |

ASTM C97/C97M-15 |

≥2.3gr/cm3 |

|

Flexural Strength |

TS EN 14617-2 |

40-65MPa |

|

ASTMC880/C880M-15 |

36-76 MPa |

|

|

Dimension Stability |

EN14617-12 |

Class A |

|

Stain, Chemical Resistance and Cleanability |

||

|

Stain Resistance Test (Polished) |

ANSI Z124.6-2007 |

Pass. Total Stain Resistance Value: 56 Maximum Individual depth of Staining: 0.04mm |

|

Chemical Resistance Test(Polished) |

ANSI Z124.6-2007 |

Pass,Unaffected |

|

Wear and Cleanability |

ANSI Z124.6 |

Pass |

|

Test Item(s) |

Test Method (s) |

Test Result(S) |

|

Durability |

||

|

Abrasive Resistance |

TS EN14617-4 |

29.0-36.0MM |

|

Mohs' Hardness (polished) |

EN101:1991 |

7 Mohs |

|

Freeze-Thaw Cycling |

ASTM1026 |

No Visual Damage |

|

Boiling Water Resistance |

ANSI NEMA LD3-3.5 |

No Effect |

|

High Temperature Resistance |

ANSI NEMA LD3-2005 |

No Effect |

|

Compressive Strength |

ASTM C170/C170M-15b |

Dry Condition: 234 MPa Wet Condition: 221MPa |

|

Impact Resistance |

EN14617-9 2005 |

5.02 J |

|

Reaction to Fire |

EN13501-1:2007 +A1: 2009 |

Bfl-S1 |

|

Thermal Shock Resistance |

ASTM -C484 |

No Visual Defects |

|

Boiling Water Resistance |

ANSI NEMA LD3-3.5 |

No Effect |

|

High Temperature Resistance |

ANSI NEMA LD3-2005 |

No Effect |

The advantages of using quartz for bathroom walls are extensive and impressive.

Quartz stones are remarkably resilient against scratches, ensuring that your bathroom walls retain their pristine appearance even after frequent use and contact.

This material is non-porous, meaning it doesn't absorb moisture, bacteria, or other impurities. This characteristic makes it an excellent choice for bathroom walls, as it helps maintain a hygienic environment.

Quartz is not only resistant to heat but also environmentally friendly. It doesn't emit any harmful radiation and is a safe choice for a space like the bathroom.

Its malleability and ease of processing make it a practical option for intricate bathroom designs. It allows for various creative installations and customizations, catering to different aesthetic preferences.

Quartz offers a wide array of color options, ensuring that it complements any bathroom decor. Additionally, its stable manufacturing process ensures consistency in quality and appearance.

In summary, when used as wall cladding in bathrooms, quartz not only provides an elegant and luxurious appearance but also ensures durability, easy maintenance, and a hygienic environment. Its resistance to scratches and impurities, along with its ease of cleaning, make it a highly sought-after material for creating stylish and functional bathroom walls.