Engineered quartz stone is a great choice for adding a pop of color and personality to your home. When used on walls, floors, countertops, and more, these quartz stones create a textured and dimensional look with their white patterns.

|

Model Number |

V042 |

|

Material |

93% quartz sand and 7% resin |

|

Surface |

Polished/Leathered/Matte |

|

Package Type |

Fumigation Wooden Frame /Iron A Frame |

|

Warranty |

More than 5 years |

|

After-sale Service |

Online technical support |

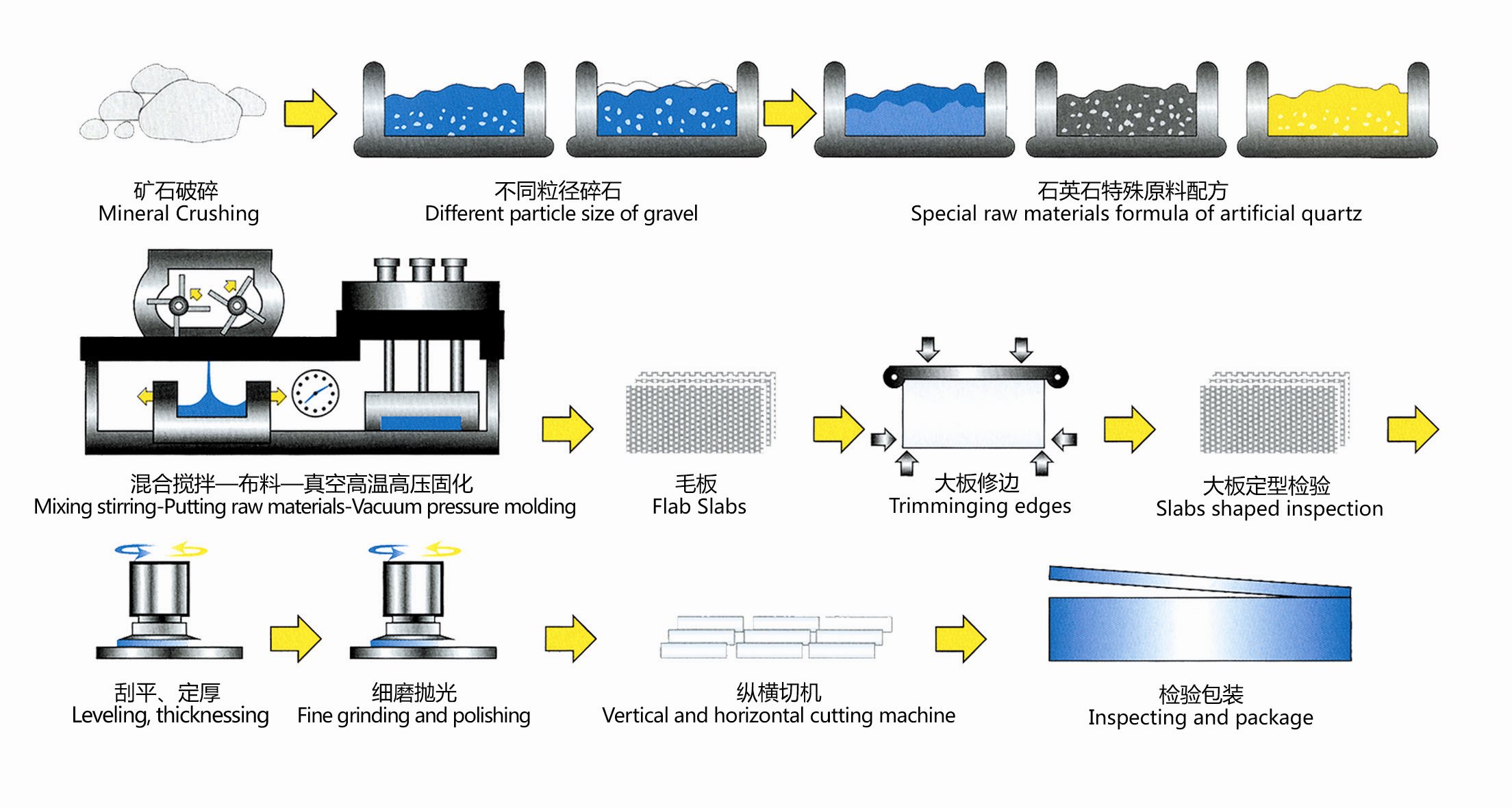

Mineral Crushing → Different particle size of gravel → Special raw materials formula of artificial quartz → Mixing stirring-Putting raw materials-Vacuum pressure molding → Flab Slabs → Trimminging edges → Slabs shaped inspection → Leveling, thicknessing → Fine grinding and polishing → Vertical and horizontal cutting machine → Inspecting and package

This series of artificial exterior stones is the ultimate fusion of sophistication and durability. Manufactured to mimic the natural beauty of stone, this quartz marvel offers a diverse range of colors and finishes, from polished sheens to captivating matte textures, seamlessly blending into any indoor or outdoor setting. Thanks to SUMMERLY Quartz's modern manufacturing technique and excellent raw materials, this series of artificial exterior stones offers several advantages:

Artificial exterior stone, like Calacatta Quartz, offers remarkable scratch resistance. This durability ensures longevity, making it an ideal choice for outdoor applications where it can withstand varying weather conditions without losing its aesthetic appeal.

Unlike natural stone, artificial exterior stone doesn't absorb impurities. This characteristic makes it easier to clean and maintain its pristine appearance over time.

The non-toxic and non-radioactive nature of engineered quartz stone ensures it remains unaffected by high temperatures. This property is especially valuable for outdoor installations subjected to direct sunlight or heat exposure.

Artificial exterior stone materials are relatively easy to process. This feature simplifies installation procedures and allows for more flexibility in design and customization.

Engineered quartz stones offer a wide range of colors and finishes. This variety allows homeowners to select from a diverse palette, providing opportunities to match different aesthetics and styles.

The consistency in texture and appearance of artificial exterior stones ensures a seamless and uniform look, especially suitable for large surfaces. This stability in the manufacturing process guarantees a uniform appearance throughout the installation.

Whether it's for walls, floors, countertops, or other outdoor architectural elements, artificial exterior stone, with its dimensional look and varied patterns, allows for versatile application, enhancing the visual appeal of outdoor spaces.

|

Test Item(s) |

Test Method (s) |

Test Result(S) |

|

Physical Properties |

||

|

Absorption by weight |

ASTM C97 |

0.03% |

|

Density |

ASTM C97/C97M-15 |

≥2.3gr/cm3 |

|

Flexural Strength |

TS EN 14617-2 |

40-65MPa |

|

ASTMC880/C880M-15 |

36-76 MPa |

|

|

Dimension Stability |

EN14617-12 |

Class A |

|

Stain, Chemical Resistance and Cleanability |

||

|

Stain Resistance Test (Polished) |

ANSI Z124.6-2007 |

Pass. Total Stain Resistance Value: 56 Maximum Individual depth of Staining: 0.04mm |

|

Chemical Resistance Test(Polished) |

ANSI Z124.6-2007 |

Pass,Unaffected |

|

Wear and Cleanability |

ANSI Z124.6 |

Pass |

|

Test Item(s) |

Test Method (s) |

Test Result(S) |

|

Durability |

||

|

Abrasive Resistance |

TS EN14617-4 |

29.0-36.0MM |

|

Mohs' Hardness (polished) |

EN101:1991 |

7 Mohs |

|

Freeze-Thaw Cycling |

ASTM1026 |

No Visual Damage |

|

Boiling Water Resistance |

ANSI NEMA LD3-3.5 |

No Effect |

|

High Temperature Resistance |

ANSI NEMA LD3-2005 |

No Effect |

|

Compressive Strength |

ASTM C170/C170M-15b |

Dry Condition: 234 MPa Wet Condition: 221MPa |

|

Impact Resistance |

EN14617-9 2005 |

5.02 J |

|

Reaction to Fire |

EN13501-1:2007 +A1: 2009 |

Bfl-S1 |

|

Thermal Shock Resistance |

ASTM -C484 |

No Visual Defects |

|

Boiling Water Resistance |

ANSI NEMA LD3-3.5 |

No Effect |

|

High Temperature Resistance |

ANSI NEMA LD3-2005 |

No Effect |