One of the most classic quartz stone styles, gold and white are well combined together, and paired with dynamic textures, it is difficult not to fall in love with this quartz stone.

|

Model Number |

V018 |

|

Material |

93% quartz sand and 7% resin |

|

Surface |

Polished/Leathered/Matte |

|

Package Type |

Fumigation Wooden Frame /Iron A Frame |

|

Warranty |

More than 5 years |

|

After-sale Service |

Online technical support |

The artificial quartz stone is flexible and its rich combination of colors gives itself with the texture and beautiful surface like the natural stone.

It can be widely used in public buildings (hotels, restaurants, banks, hospitals, exhibitions, laboratories, etc.) and home decoration (kitchen countertops, washstands, kitchen and bathroom walls, dining tables, coffee tables, window sills, door covers, etc.). It is an environmentally new building interior decoration material that is free of radioactive pollution and can be reused.

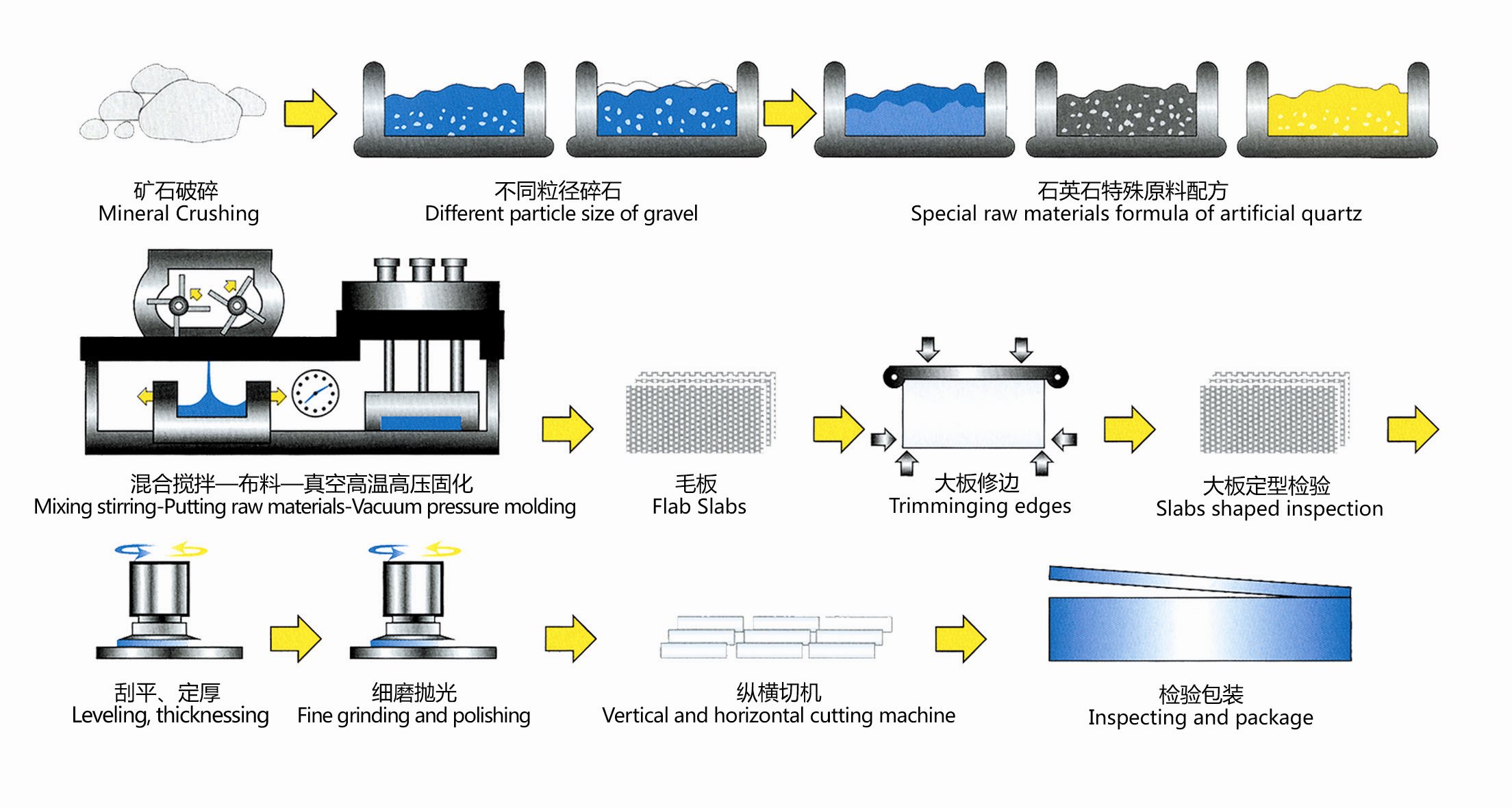

Mineral Crushing → Different particle size of gravel → Special raw materials formula of artificial quartz → Mixing stirring-Putting raw materials-Vacuum pressure molding → Flab Slabs → Trimminging edges → Slabs shaped inspection → Leveling, thicknessing → Fine grinding and polishing → Vertical and horizontal cutting machine → Inspecting and package

|

Test Item(s) |

Test Method (s) |

Test Result(S) |

|

Physical Properties |

||

|

Absorption by weight |

ASTM C97 |

0.03% |

|

Density |

ASTM C97/C97M-15 |

≥2.3gr/cm3 |

|

Flexural Strength |

TS EN 14617-2 |

40-65MPa |

|

ASTMC880/C880M-15 |

36-76 MPa |

|

|

Dimension Stability |

EN14617-12 |

Class A |

|

Stain, Chemical Resistance and Cleanability |

||

|

Stain Resistance Test (Polished) |

ANSI Z124.6-2007 |

Pass. Total Stain Resistance Value: 56 Maximum Individual depth of Staining: 0.04mm |

|

Chemical Resistance Test(Polished) |

ANSI Z124.6-2007 |

Pass,Unaffected |

|

Wear and Cleanability |

ANSI Z124.6 |

Pass |

|

Test Item(s) |

Test Method (s) |

Test Result(S) |

|

Durability |

||

|

Abrasive Resistance |

TS EN14617-4 |

29.0-36.0MM |

|

Mohs' Hardness (polished) |

EN101:1991 |

7 Mohs |

|

Freeze-Thaw Cycling |

ASTM1026 |

No Visual Damage |

|

Boiling Water Resistance |

ANSI NEMA LD3-3.5 |

No Effect |

|

High Temperature Resistance |

ANSI NEMA LD3-2005 |

No Effect |

|

Compressive Strength |

ASTM C170/C170M-15b |

Dry Condition: 234 MPa Wet Condition: 221MPa |

|

Impact Resistance |

EN14617-9 2005 |

5.02 J |

|

Reaction to Fire |

EN13501-1:2007 +A1: 2009 |

Bfl-S1 |

|

Thermal Shock Resistance |

ASTM -C484 |

No Visual Defects |

|

Boiling Water Resistance |

ANSI NEMA LD3-3.5 |

No Effect |

|

High Temperature Resistance |

ANSI NEMA LD3-2005 |

No Effect |

The artificial quartz stone countertop offers practical benefits to thousands of users. Here are the main advantages of using artificial quartz stone countertops.

Artificial quartz stone countertops offer exceptional scratch resistance, ensuring a long-lasting surface that can withstand the wear and tear of daily use. This feature contributes to the durability and longevity of the countertop.

The non-porous nature of quartz prevents the absorption of liquids and impurities, making it highly resistant to stains. This characteristic ensures easy cleaning and maintenance, as spills and stains can be easily wiped away without leaving a mark.

Quartz countertops exhibit excellent heat resistance, making them suitable for use in kitchens where hot pans or pots are commonly placed. Additionally, being non-toxic and non-radioactive ensures a safe environment for food preparation.

The ease of processing quartz stone allows for precise customization and shaping according to specific design requirements. This feature facilitates seamless integration into various kitchen or bathroom layouts.

Quartz countertops come in a wide range of colors, allowing homeowners to choose from a diverse palette that matches their aesthetic preferences and interior design. The flexibility in colors ensures versatility in complementing different styles and décor themes.

The stability in the manufacturing process guarantees consistent quality across all countertops. This reliability ensures uniformity in characteristics such as durability, color, and finish.