Engineered quartz stone is a great choice for adding a pop of color and personality to your home. When used on walls, floors, countertops, and more, these quartz stones create a textured and dimensional look with their white patterns.

|

Model Number |

V029 |

|

Material |

93% quartz sand and 7% resin |

|

Surface |

Polished/Leathered/Matte |

|

Package Type |

Fumigation Wooden Frame /Iron A Frame |

|

Warranty |

More than 5 years |

|

After-sale Service |

Online technical support |

The artificial quartz stone is flexible and its rich combination of colors gives itself with the texture and beautiful surface like the natural stone.

It can be widely used in public buildings (hotels, restaurants, banks, hospitals, exhibitions, laboratories, etc.) and home decoration (kitchen countertops, washstands, kitchen and bathroom walls, dining tables, coffee tables, window sills, door covers, etc.). It is an environmentally new building interior decoration material that is free of radioactive pollution and can be reused.

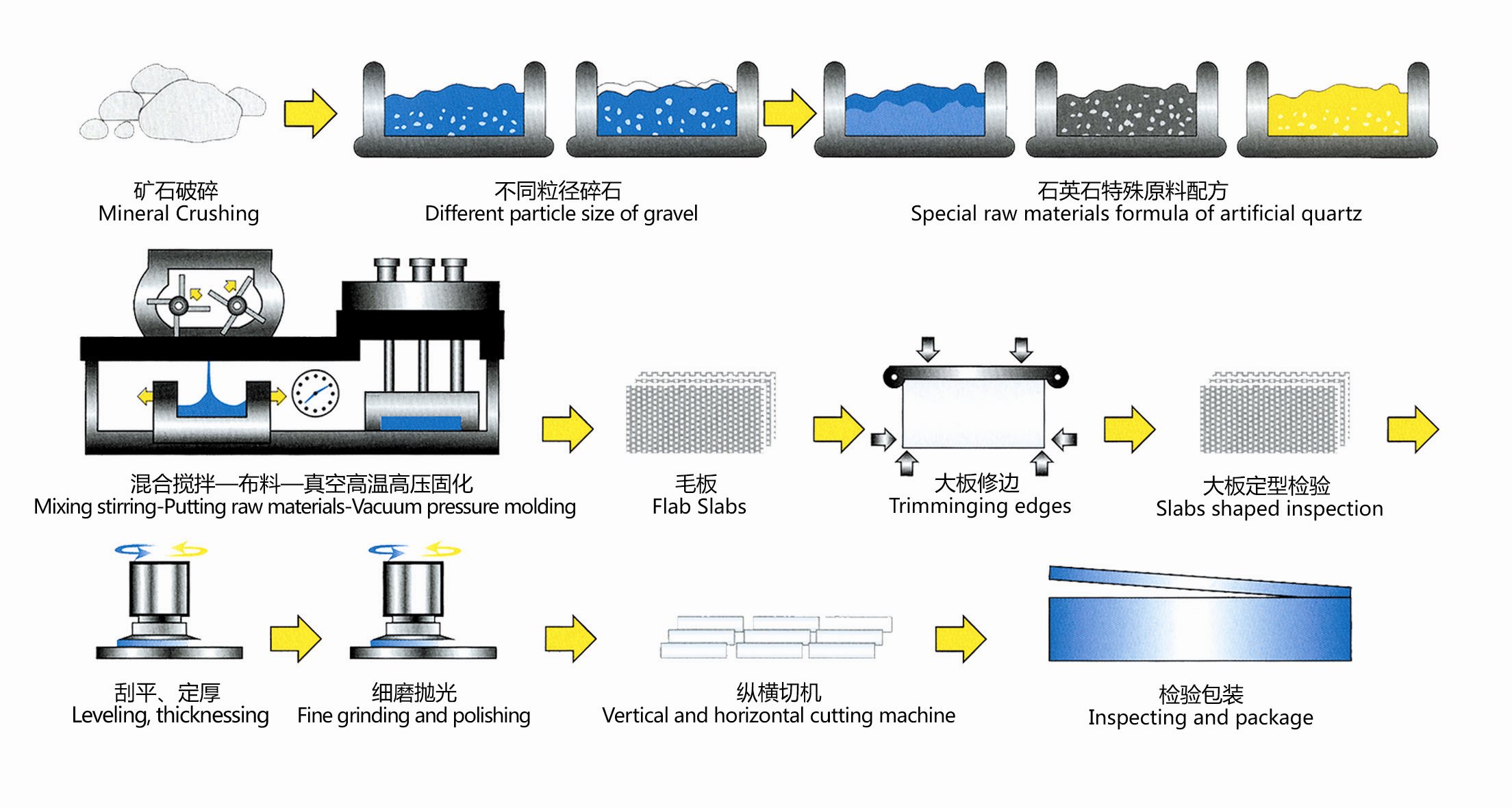

Mineral Crushing → Different particle size of gravel → Special raw materials formula of artificial quartz → Mixing stirring-Putting raw materials-Vacuum pressure molding → Flab Slabs → Trimminging edges → Slabs shaped inspection → Leveling, thicknessing → Fine grinding and polishing → Vertical and horizontal cutting machine → Inspecting and package

|

Test Item(s) |

Test Method (s) |

Test Result(S) |

|

Physical Properties |

||

|

Absorption by weight |

ASTM C97 |

0.03% |

|

Density |

ASTM C97/C97M-15 |

≥2.3gr/cm3 |

|

Flexural Strength |

TS EN 14617-2 |

40-65MPa |

|

ASTMC880/C880M-15 |

36-76 MPa |

|

|

Dimension Stability |

EN14617-12 |

Class A |

|

Stain, Chemical Resistance and Cleanability |

||

|

Stain Resistance Test (Polished) |

ANSI Z124.6-2007 |

Pass. Total Stain Resistance Value: 56 Maximum Individual depth of Staining: 0.04mm |

|

Chemical Resistance Test(Polished) |

ANSI Z124.6-2007 |

Pass,Unaffected |

|

Wear and Cleanability |

ANSI Z124.6 |

Pass |

|

Test Item(s) |

Test Method (s) |

Test Result(S) |

|

Durability |

||

|

Abrasive Resistance |

TS EN14617-4 |

29.0-36.0MM |

|

Mohs' Hardness (polished) |

EN101:1991 |

7 Mohs |

|

Freeze-Thaw Cycling |

ASTM1026 |

No Visual Damage |

|

Boiling Water Resistance |

ANSI NEMA LD3-3.5 |

No Effect |

|

High Temperature Resistance |

ANSI NEMA LD3-2005 |

No Effect |

|

Compressive Strength |

ASTM C170/C170M-15b |

Dry Condition: 234 MPa Wet Condition: 221MPa |

|

Impact Resistance |

EN14617-9 2005 |

5.02 J |

|

Reaction to Fire |

EN13501-1:2007 +A1: 2009 |

Bfl-S1 |

|

Thermal Shock Resistance |

ASTM -C484 |

No Visual Defects |

|

Boiling Water Resistance |

ANSI NEMA LD3-3.5 |

No Effect |

|

High Temperature Resistance |

ANSI NEMA LD3-2005 |

No Effect |

The black quartz engineered stone is one of the most classic and universal products in the stone collections. And, the black quartz engineered stone presents the most elegance and delicacy. The sophisticated black and simple lines create a perfect artwork altogether.

The black quartz engineered stone maintains its beauty meanwhile having an excellent performance in functionality.

First, the black quartz engineered stone stands resilient against scratches, maintaining its pristine allure even with daily use.

Second, the black quartz engineered stone contains non-radioactive compositions and maintains its purity in long-term use. Also, it repels impurities, ensuring a surface that remains pristine and untainted over time, maintaining its elegance effortlessly.

Third, manufactured with advanced techniques, the black quartz engineered stone guarantees both safety and durability, making it a reliable choice for any environment. The black quartz engineered stone can be applied to the kitchen, living room, bathroom, etc.

Then, discover the epitome of sophistication and endurance with our black quartz engineered stone, where elegance meets resilience, and quality exceeds expectations. Elevate your space with a touch of sophistication and durability that only our product can deliver.

Fourth, boasting an absorption rate of a mere 0.03% by weight and a density of ≥2.3gr/cm3, our black quartz engineered stone excels in dimensional stability, earning it a Class A rating. It remains unaffected by boiling water and high temperatures, ensuring its durability even in the most demanding conditions.

Fifth, the black quartz engineered stone showcases a compressive strength of 234 MPa in dry conditions, emphasizing its robustness and reliability.

Cleaning the quartz stone countertops is an easy job because it has a smooth and even surface and is easy to clean. Here are the steps to clean your countertops:

Step 1: Use a Soft Cloth

Wipe down the countertops with a soft cloth or sponge and warm, soapy water. Mild dish soap works well.

Step 2: Rinse Thoroughly

After cleaning, rinse the countertops with clean water to remove any soap residue.

Step 3: Dry with a Soft Cloth

Use a dry, clean cloth to wipe the surface dry to prevent water spots or streaks.

Generally speaking, ordinary engineered quartz stone countertops are not heat resistant. If ordinary engineered quartz stone countertops are directly in contact with a hot pot or pan, they would get damaged. Thus, most people usually use a trivet to protect quartz.

However, engineered quartz stone countertops produced by Summerly are heat resistant. Summerly engineered quartz stone countertops have no effect on the high-temperature resistance tests of ANSI NEMA LD3-2005.

Quartz countertops are generally resistant to staining due to their non-porous nature.

However, while quartz is highly stain-resistant, it's not completely impervious. Certain highly pigmented substances or harsh chemicals left on the surface for an extended period might cause discoloration or staining. For instance, prolonged exposure to harsh chemicals or solvents could affect the resin in the quartz.